This is How it works

Innovative fish farming in industrial symbiosis with the forest industry

Reduced costs – Improved environmental performance – New billion industry for Sweden

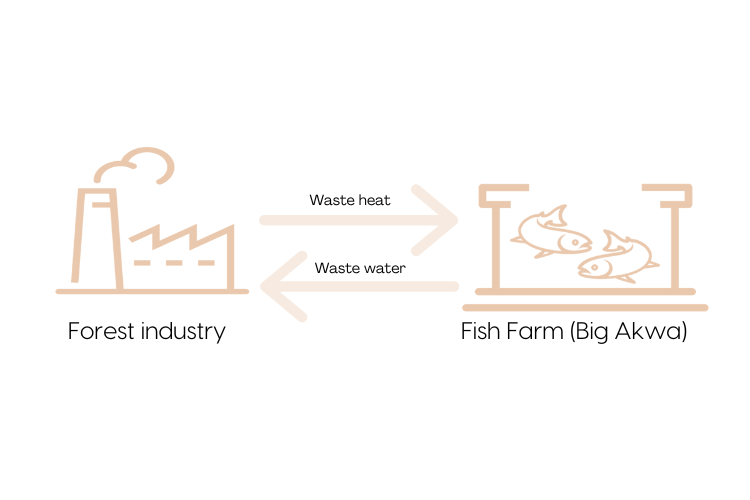

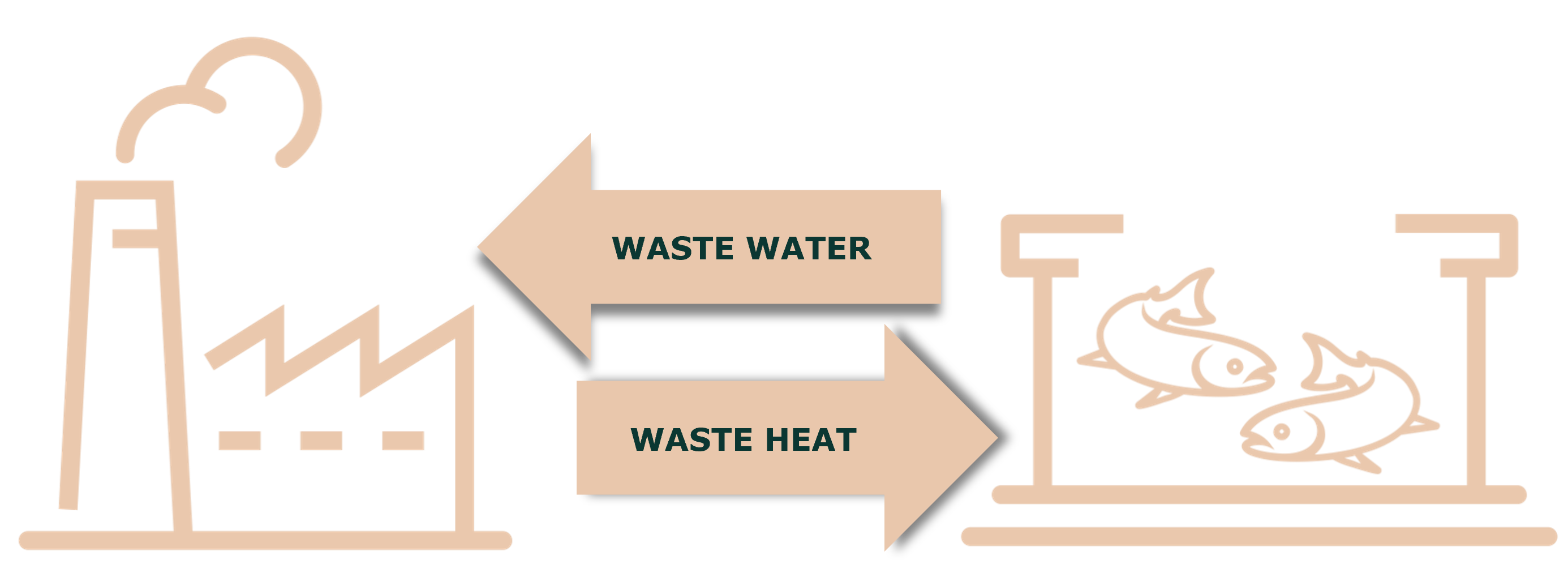

Co-located fish farming system and the forest industry working together synergistically and sustainably.

The pulp industry generates low temperature heat that is typically wasted in production. This heat can be used to warm up fish farm water to optimal temperatures ensuring faster fish growth and lower energy usage.

Fish farms produce “dirty water” that tends to get released into surrounding waters causing serious environmental problems. However, this dirty water happens to be a favorite food source for the bacteria pulp producers use in the water purification steps.

By recycling dirty fish water and feeding it back into pulp production, considerable energy savings may be realized while improving the environmental footprint of both fish and pulp production.

INTEGRATION BASED ON WASTE

FLOW RE-USE

Nitrogen and phosphorus from fish farm to mill water treatment

Low grade heat from mill to warm up fish water.

Concept Benefits

Mill

Reduced purchase of chemicals

Sales of low grade heat

Rent of premises.

Fish farm

Lower production cost

Reduced capital investments.

Mutual

Reduced carbon footprint

Synergies of co-location.

Advancing Industrial Symbiosis within forest industry

Current status: TRL 5

We’ve successfully tested and validated this technology over three years in collaboration with Veolia and SCA Group, one of the global leader in the forest industry. The testing phase has demonstrated economical benefits and carbon footprint reductions, which have been computed and certified by Processum.

Large European Investment institutions has shown strong interest in supporting the project. Moreover we’ve secured a Letter of Intent (LOI) with SCA and are in advanced negotiations with other key industry players, including Metsä Group (Husum), Södra, and several smaller mills to evaluate best location for industrial scale .

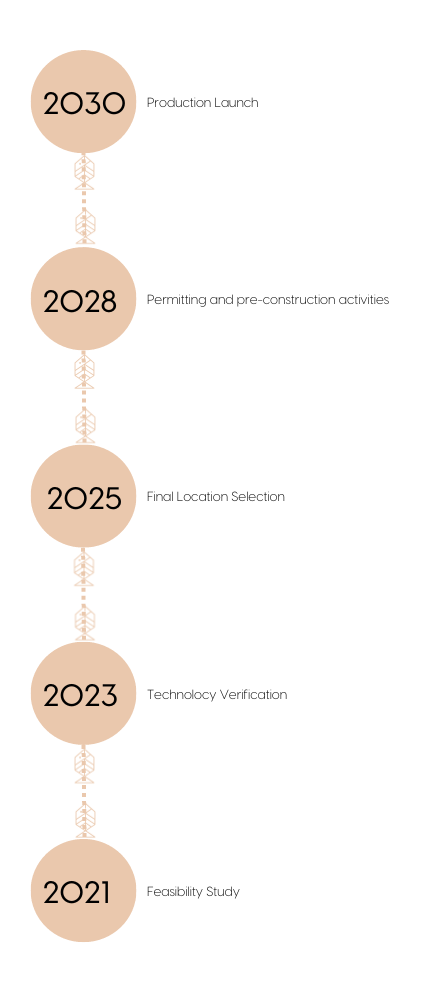

Roadmap